SER903011 Serpent Serpent 966 -TE V2 1/8 Scale 4WD

$355.65 Original price was: $355.65.$96.99Current price is: $96.99.

- Safeguard Your Shopping Experience

- Experience Quality, Shop with Us

- No Compromise on Quality

- Shop the Best Quality Online

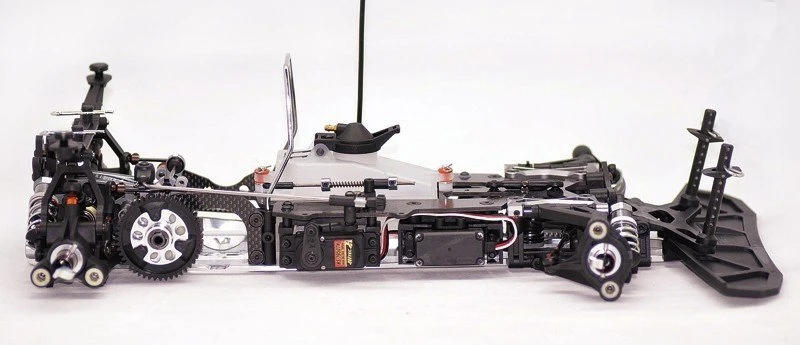

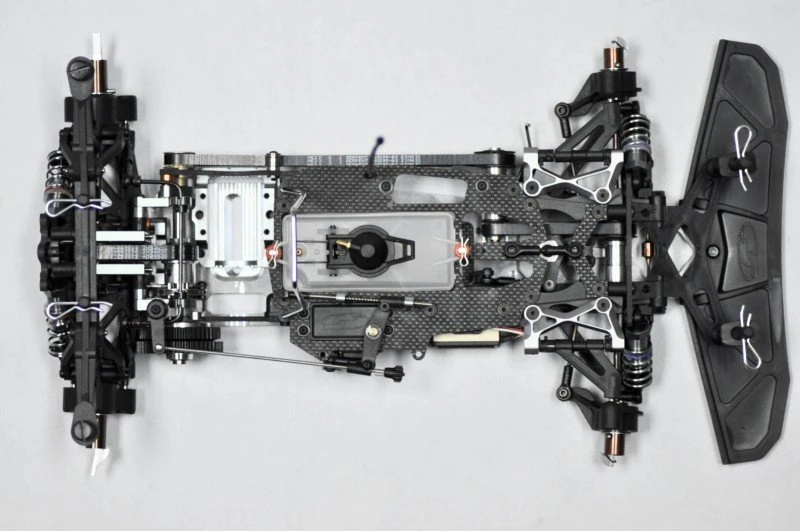

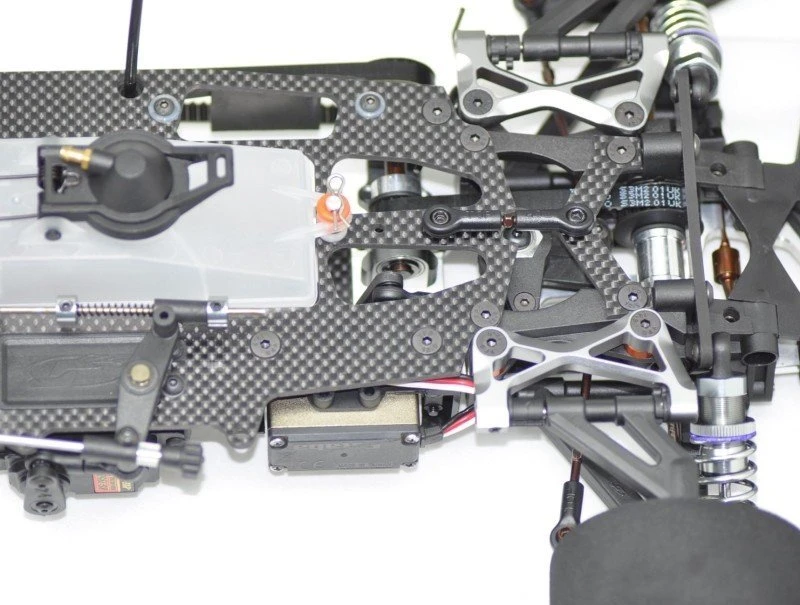

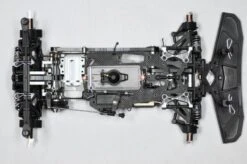

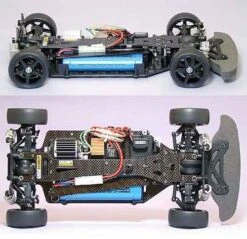

Serpent 1/8 scale 4wd gaspowered racing car chassis in the Team edition v2.

Specifications:

- Class: 1/8th scale gas on-road, IFMAR rules

- Purpose: High-end competition

- Weight: 2.520kg (depending on radio gear)

- Track-width rear: 260mm – 266mm

- Track-width front: 250mm – 260mm

- Wheel base: Adjustable 296 – 300mm +/-1.7mm

- Chassis: 5mm 7075 aerospace quality aluminium, precision CNC machined

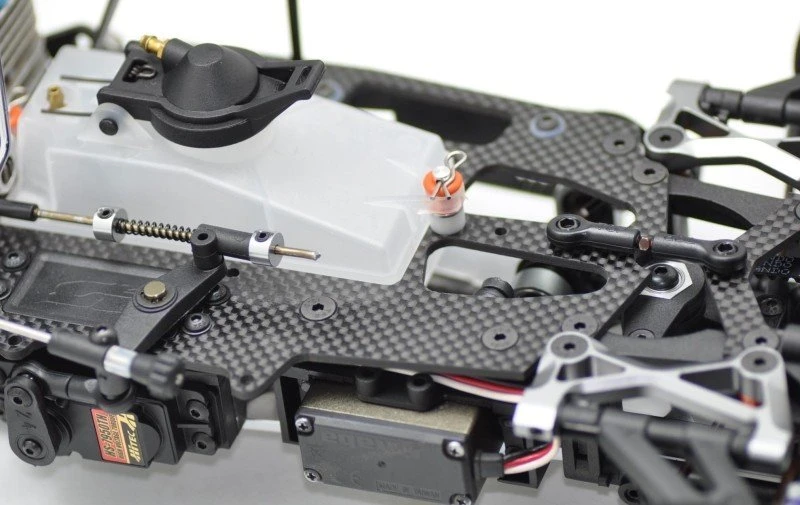

- Radio plate: 2.5mm carbon fibre

- Suspension: Independent double wishbone suspension

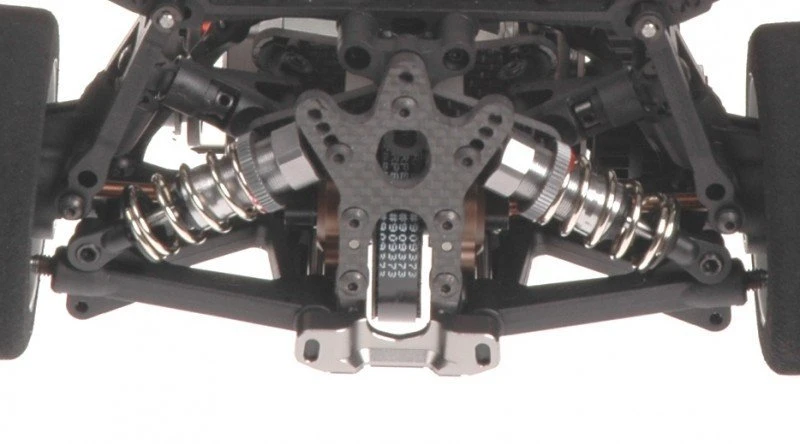

- Shock absorbers: RCM shock absorbers

- Fuel tank: 125cc design

- Rear axle: Solid rear axle

- Front axle: Aluminium front axle with one-way bearings

- Gearbox: Lightweight 2-speed SL8

- Clutch system: Centax true Motion clutch system, hard anodized alu. gears

16-19T std - Adjustability: Camber, Caster, Down-stops, Up-stops, Toe-in, Track width,

Wheel base, Front and rear roll centre

Features:

- Centax True Motion clutch system

- RCM shocks

- SL8 gearbox included, for lower inertia

- Front aero bumper

- split-type carbon radioplate with flex-control

- New front upper geometry with inner pivots more out and shorter upper arms

- New rear upper geometry wth new camber-bracket and upper camber-rods instead

wishbone - Rear lower shockmounts/extenders in carbon

- New style tank-top/tank-cap ( same as S811 )

Rear end connectors

Rear end connectors in rubber and alu, to influence rear end flex.

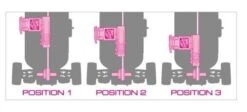

Steering Blocks

These Wide offset (WOS) steering blocks can be used in 2 different configurations

by swapping the side of the car they are mounted on. These changes, depending

on the side the steering blocks are used on, will either give you more turn

in on corner entry, or more on power steering at corner exit.

The included eccenters ensure that the axle is raised higher than centre line,

which enhances the effect caused by this new configuration and due to the use

of eccenters the bearings are now also smaller and lighter, reducing un sprung

weight.

Front Bumper and Body Mount

The front body mount of the Serpent 966 is screwed down along with the bumper,

which allows for some flex in the body post mounts whilst maintaining the stiffness

of the overall assembly. The body mount is held further through two screws mounted

from the side.As with the rear roll centre, the front roll centre can also be

easily adjusted. The adjustment is done by removing the front upper suspension

brackets and inserting spacers below the brackets and then re-attaching them

to the car.

The 966 comes with anodised aluminium front upper suspension brackets that

are machined from a single piece of aluminium. These attractive pieces are extremely

strong and offer great protection in the event of a heavy impact. The other

great advantage of this part is that due to the use of inserts, with an offset

hole, you can now adjust the pivot position of the upper front wishbones. Another

nice design feature is that the same front suspension bracket can be used on

both the left and right sides of the car.

Thew new aero bumper can be used closed, or partially open, by cutting out the

aligned inner parts.

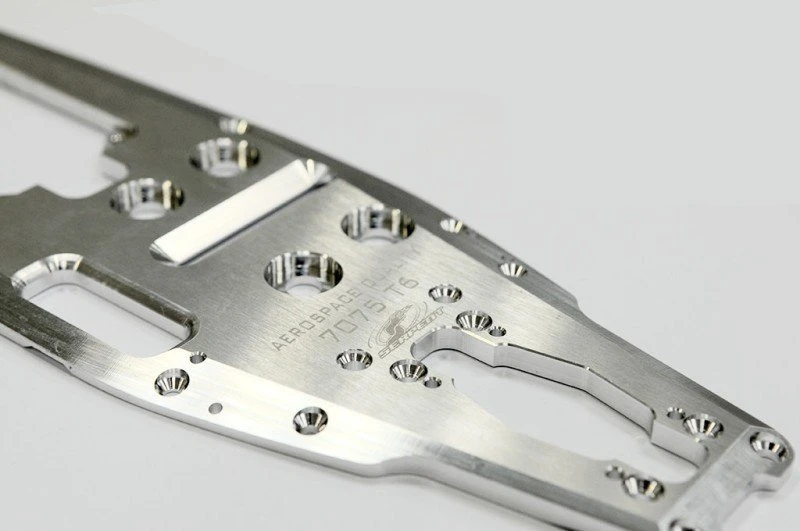

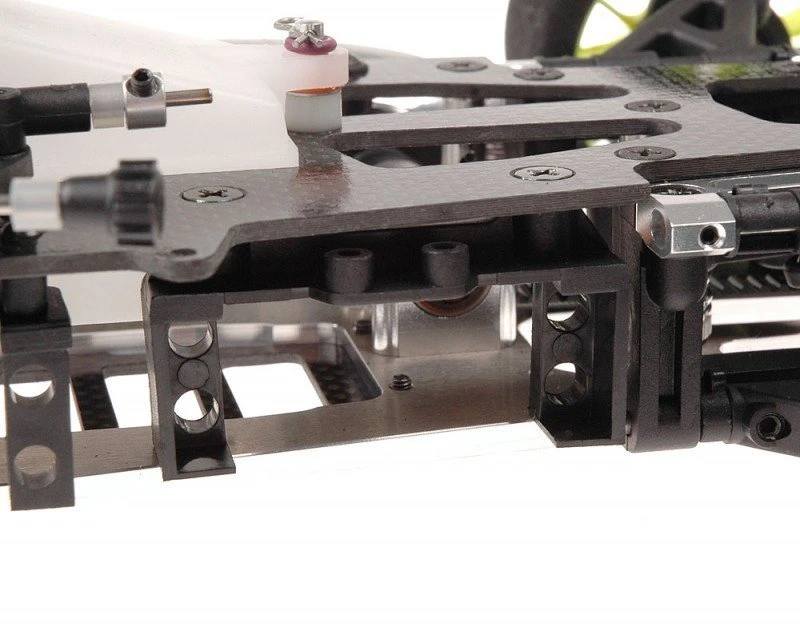

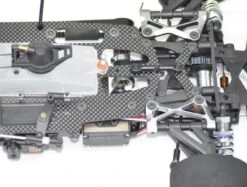

Chassis Plate

The backbone of the car is the chassis plate, which has been CNC-machined from

extremely stiff american 7075 T6 – 5mm aerospace-quality aluminium and sports

a wide front opening to adjust the front anti-roll bar. A cooling slot under

the engine helps aid temperature control while chamfered edges prevent the chassis

from catching on kerbs giving it better overall ground clearance on the track.

It houses the battery pack, which is mounted into the newly-designed carbon

fibre battery mounting plate and is held in place by four screws, screwed directly

into the chassis plate itself. This 966-TE plate has also been machined to accept

the optional front stiffener plate.

Brake-system

The brake system ensures strong and efficient stopping power. The brake pads

consist of two steel plates with the friction material pre-baked to the plates,

and the brake disk is made from twin ventilated discs with an air-cooling alu

centre.The new braking system sits lower in the car to help LCG. The system

is easily accessable for maintenance, due to its very open design.

The spring-loaded bar-pads slide on polished steel pins and are activated through

the ball-raced brake cam, a large pin moves horizontally to activate the brakes.

Due to the horizontal action of the pin, and not the twisting of the brake cam,

all distortion in this area is removed and the brake pads are evenly pressed

together. The brake cam is supported by ball-bearings for smooth, precise action.

This further adds to the precision and exceptional stopping power of the braking

system.

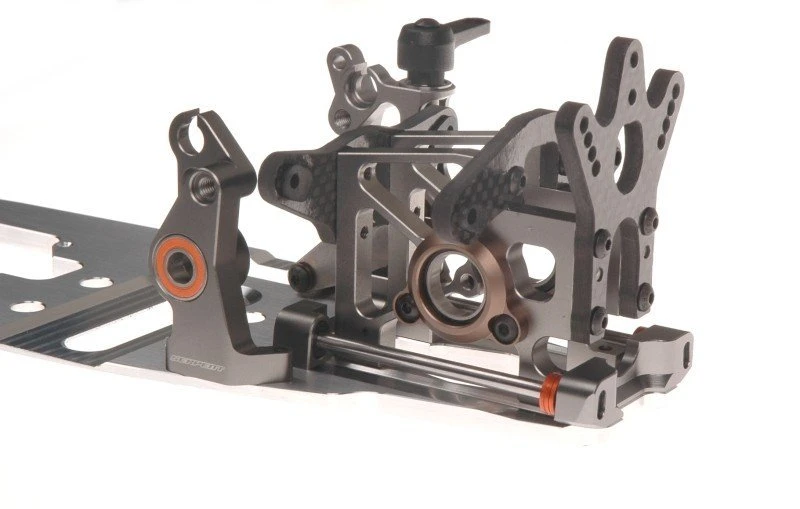

Brake 966

Lower mounted brake-assembly for lower LCG. Spring-loaded brake-plates slides

on polished steel shafts. Ready-to-run brake plate/pads assembly with new friction

brake material. The ball-raced hard anodized brake-cam push the 2 larger pins

which are seated in the aluminium bracket, against the brakeplat, to create

very smooth and even pressure to the plate.

RCM Shock Absorbers

The RCM shock absorbers are super-smooth and very easy to build. Coated aluminium

threaded shock-bodies, perfect pistons, smooth o-ring-bushing package, effective

silicone membranes, durable hardened shock-rods, the works !

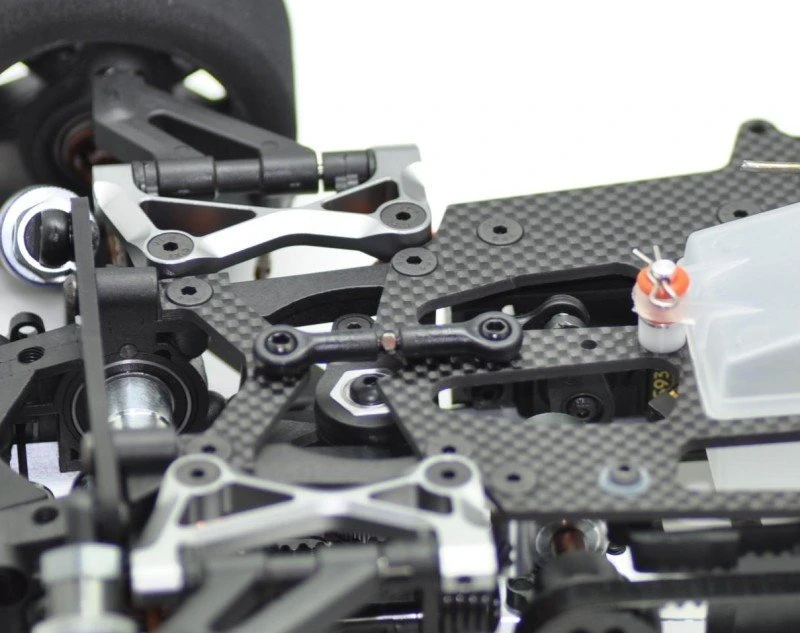

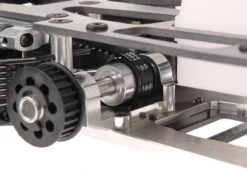

Main rear brackets

Anodized, cnc machined, aluminum main rear axle supports with coated alu eccenters;

more rigid, better rear axle support for a very true running rear shaft, easy

belt-tensioning, easy access for maintenance. With the eccenters you can choose

3 positions for rear- belt tensioning. By removing the eccenter on one side

the rear shaft with pulley and belt can be accessed very easily. Main rear supports

are machined maximum to reduced weight, but retain rigidness at the same time.

Pins are pre-pressed into the bottom of the brackets which then seat into the

positioning holes in the chassis. Precise and secure.

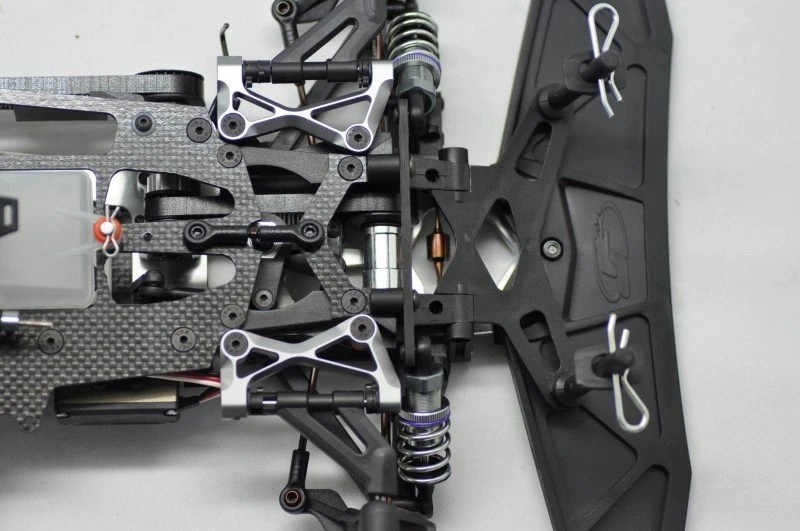

Front Suspension

The front anti-roll bar levers, that are combined with the down stops allowing

for easier tweak. They placed inwards, inside the bearing-blocks, which makes

them more effective due to less flex. The front lower arms accommodate the front

anti-roll bar position.

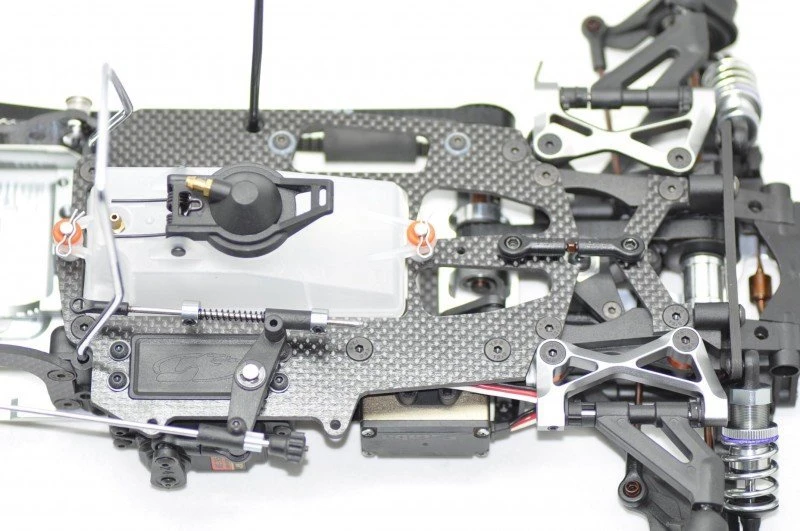

Battery Mounting Plate

The carbon fibre battery mounting plate has been designed to be able to accommodate

many different battery pack configurations, including the traditional 5 cell

pack. The battery mounting plate is made of a 2mm black carbon fibre and is

mounted to the chassis plate by four countersunk screws.

Radio Plate Support Bracket

The radio plate support bracket, placed directly in front of the engine, also

acts as the mounting point for the roll over bar.

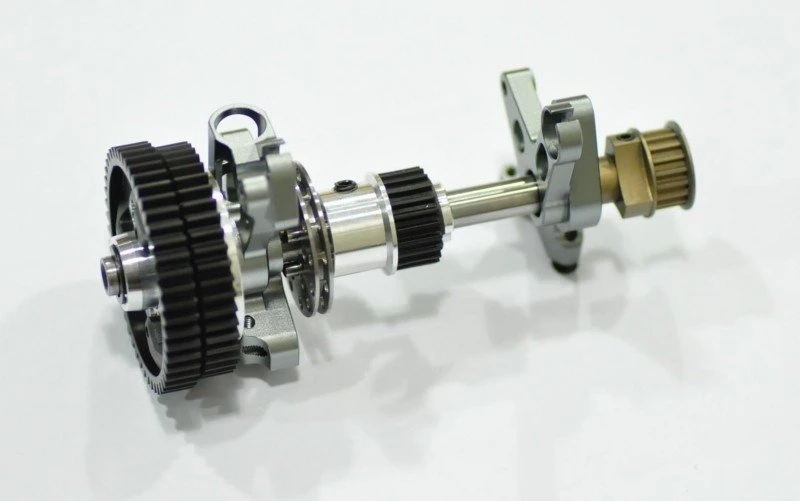

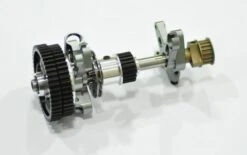

SL8 gearbox

The 966-TE included the latest developed Serpent gearbox with 8mm shaft and

new flange, bell and gears. A perfectly balanced gearbox with very low inertia,

and a perfect bearing seating.

Durable and ultra quick shifting.

The brake-disk and pulley-adaptor with 3 pins has been modified, and a new

alu hardcoated side pully in included to fit the 8mm shaft.

Split-type radioplate

The 966-TE features a split type radioplate. The larger central parts connects

with a rod to the front stiffner. The central part front screws which connect

to the bulkheads can be loosened to create more flex; the rod will control the

flex.

testing showed that flex in the front has more effect than in the rear or central

part of the chassis.

Adjustable Front Belt Tension

A great feature is the ability to adjust the tension of the front belt. The

simple-to-use bearing eccentric holders allow for quick and easy setting.

Front Shock Tower

The front shock tower of the Serpent 966 is made from 3mm carbon fibre, which

makes this part ultra crash resistant. The front shock tower also features two

shock mounting positions to enable you to fine tune your car for any track conditions.

Driveshafts / wheelaxles

Serpent use only the highest-quality drive train in their cars. The 966 car

comes supplied with the finest Spring Steel drive shafts capable of withstanding

constant punishment; these shafts are ultra durable and very stiff allowing

you to put all your power to the tarmac.

Front CVD and rear regular dogbones.

Made from Spring Steel, the front and rear wheel axles are very durable and

ultra strong. They are a precision fit for the main bearings when mounted with

the supplied shims to ensure a tight precise wheel fit. The front axle also

makes up part of the CVD shafts that are included in this kit and can therefore

be used with both the supplied quick release system or the optional wheel nuts.

Pivot Balls

Made from Spring Steel, these polished 8.5mm pivot balls are virtually unbreakable

and ensure the smoothest suspension movement possible.

Adjusting nut for pivot balls

These adjusting nuts are made from Nylon and replace the previous aluminium

nut with plastic insert which will not only makes assembly easier, it also reduces

un-sprung weight. Reducing the parts used at this point also reduces side play

so it makes for a more precise handling car and because the material used is

self-lubricating the movement of the pivot ball will remain smooth throughout

use.

Aluminium middle bracket

The Serpent 966 comes supplied with an aluminium middle bracket as standard.

Replacing the standard composite version, the new part is much stiffer and so

reduces flex in this axle which prolongs the life of the belts and pulleys.

Front Axle

The front axle is made from high-grade aluminium and contains the best quality

one-way bearings lubricated with one-way lube. This ensures a consistent drive

to the front Spring Steel drive cups.

Front Anti-roll Bar

The Serpent 966-TE comes standard with an adjustable front anti-roll bar. By

rotating the 2 blades, you can easily adjust the stiffness. Centering with an

improved adjuster eccentric.

Chassis Stiffeners

Another feature is the two carbon-fibre side mounted chassis stiffeners. These

plates form a strong bridge between the front and rear section of the 960, and

are mounted directly to the radio plate bracket and to the rear bulkheads. They

increase the chassis stiffness, an essential condition to make effective use

of the sophisticated suspension adjustment options. The left chassis stiffener

doubles as a belt-tensioner holder to with a longer slot to enable changes.

Fuel Tank

Serpent have supplied the 125cc fuel tank with a silicone rubber seal for the

fuel tank lid that prevents leakage and thus provides more consistent engine

performance. Made from silicone rubber, the new seal has been shaped to create

a perfect seal around the opening of the tank and allowing the tank lid to close

fully.

The tank is made from a newer stronger material. The tanks have more resistance

to shattering in the event of a heavy impact and changes to the lid pivot pin

position further ensure a perfectly sealed tank. The new material is also less

heat sensitive and will keeps it shape better also when hot. The tank offers

the option to mount small spacers inside to fine-tune the volume.

Receiver Mounting

The receiver on the Serpent 966 can be mounted in two different positions, depending

on whether you choose the laydown throttle servo mounting or the traditional

upright throttle servo mounting.

If you mount the throttle servo using the laydown configuration, the receiver

is mounted on the left side of the radio plate, between the fuel tank and the

exhaust system.

If you mount the throttle servo using the traditional upright configuration,

the receiver (and protective cover) can be mounted next to the throttle servo.

The benefit of these alternative mounting positions is that it offers choices

for electronics placement, as well as options for eliminating any recurring

interference issues that may occur.

Steering Servo Mounting

The steering servo is mounted on the right side directly to the bottom of the

radio plate and hangs free from any other item. The steering system uses a centrally

mounted servo-saver, which features adjustable spring tension and comes with

four Ackerman options, through the use of inserts, to help fine-tune the 966-TE

steering characteristics. Adjustable steel track rods with left and right threads

are standard.

Rear Axle

Made from Spring Steel, the solid rear axle is very durable and ultra strong

providing a perfect base to mount the rear drive pulley. A steel pin secures

the pulley and an o-ring keeps it in place.

Adjustable Rear Roll Center and Camber Rise

On the Serpent 966-TE the rear roll centre is adjustable through the use of

offset composite inserts, which position the wishbone pivot pins of the lower

wishbones.The rear camber rise can also be adjusted through the same method

but on the upper rear wishbone pivot pins. The use of composite inserts means

both adjustments can be easily made track side.

Rear Anti-roll Bar

The wire type rear anti-roll bar on the Serpent 966 is ball-raced for extra

precision and more accuracy.The blade type rear anti-roll bar is optional.

Rear Body Mount

The rear body mount on the Serpent 966 can be connected in several different

ways to increase or decrease the downforce transmitted from the body to the

rear wheels. There are longer body mount arms, that are mounted to the rear

uprights at axle level which provides more down force to the wheels. The whole

assembly is also free from binding, meaning there is no restriction of the movement

on the suspension.

Rear Suspension

The rear end geometry provides excellent rear end grip and provides a very stable

car both under braking and at exiting corners. The OS 2 uprights sport small

bearings to reduce un sprung weight, 3 upper arm mounting positions and the

possibility to use shims for changing the roll centres. Strong lower wishbones

with sufficient material around the pivot pin and pivot balls, and the upper

arms allow easy adjustment of the camber and camber rise. Longer body mount

arms provide more down force to the wheels yet have no binding due to their

mounting position.

Rear Shock Tower

The rear shock tower of the Serpent 966 is made from 3mm carbon fibre, which

again makes this part ultra crash resistant. The rear shock tower sports 4 shock

mounting positions to help you fine-tune your cars handling track side.

Quick Release Wheel System

The Serpent 966-TE comes standard with both spring-loaded aluminium quick release

levers.

Quick-change

This reliable and time-saving system enables very quick tire changes during

long distance races, allowing you to get back on the track in as little time

as possible.

Adjustable Wheelbase

Due to the front wishbone configuration, it is possible to very easily adjust

the car’s wheelbase through the placement of 1 upper and lower caster clip on

each side of the car. In the rear you can place shims in front or at the rear

of the lower rear wishbones to obtain plus or minus 3mm.

Throttle Servo Mounting

The 966-TE offers two possibilities for the mounting of the throttle servo,

first of which is the the traditional stand-up throttle servo layout. To lower

the cars centre of gravity there is also an option to mount the throttle servo

in a lay down configuration. This moves the heavy motor and other parts of the

servo lower and to the inside allowing for better weight distribution and C

of G.

The lay down throttle servo assembly has been designed to fit in the standard

servo mounting space, thus enabling the easy change over between configurations.

If you decide to use the traditional upright mounting, you can mount the receiver

next to the throttle servo. Otherwise the receiver is in its standard place

on the left side of the radio plate.

Drive Belt System

The Serpent 966-TE uses three Kevlar-reinforced main drive belts, driven by

a series of composite pulleys mounted on aluminium pulley adapters. This allows

for a very smooth and efficient drive system that can withstand severe punishment.

Engine Mono block

The strong engine mono block that takes advantage of the extra space where the

engine is mounted on the LCG (Low Center of Gravity) chassis plate. As well

as the benefits of the mono block system, to stop the engine flexing, the block

allows the motor to be mounted lower in the chassis by 2mm. Due to the engine

being lowered the car is now supplied with a smaller diameter flywheel.

Centax True Motion Clutch

Serpent introduces new Centax clutches for 1/8 onroad. Many variations have

been tried, but in the end it still comes close to the original idea.In the

latest development the tapered shape has been moved from the flywheel to the

pressure plate instead, improves punch and reliability. Serpent continues the

use of the hard Centax spring to set preload, as its less critical and faster

to adjust.

The 1/8 scale Centax True motion clutch, has the black shoe and aluminum cutch

housing as standard. Yellow and red shoes can be tried as well, as well as the

steel or light steel clutch housing.

Exhaust Mounting Spring

Using a spring-type mounting wire to isolate vibrations, the spring is attached

to the car by means of an aluminium mounting post attached to the radio plate.

Gearbox

The SL8 2-speed gearbox is race proven and is easy to adjust and assemble thanks

to its simple design. The gearbox features large ball bearings for extra durability

and smoother rotation. The 8mm shaft will offer increased stability.The new

2-speed gears are mounted to the carriers with three small screws and come in

a full range of gears available in combination with pinions for the Centax-II

clutch.

Bearings

Supplied with sealed high-quality lightweight bearings throughout, the drive

train is very efficient and runs very smoothly.

30 bearings in total including 3 one-ways.

Adjustment

The Serpent 966 is a top-level competition racer and is therefore fully adjustable.

The racer can change numerous settings easily and effectively, including the

suspension geometry. The down stops can be easily accessed and easily adjusted

with optimum effect. Caster, track-width, toe-in, camber, camber rise, and wheelbase

can also be adjusted with ease, as well as the front and rear roll-centre and

rear body mount mounting angle.

Be the first to review “SER903011 Serpent Serpent 966 -TE V2 1/8 Scale 4WD” Cancel reply

Related products

R/C On-Road Car

M-Chassis Cars

R/C On-Road Car

R/C On-Road Car

R/C On-Road Car

32233R Kyosho – Enzo GT Concept MR-03 Sports 2 Mini-Z R/S Readyset With 2.4GHz KT-19 Transmitter

R/C On-Road Car

32798 Kyosho – MINI-Z Racer MR-03EVO Chassis Set (N-MM2/4100KV)

R/C On-Road Car

Reviews

There are no reviews yet.