SER903015 Serpent Viper 977 EVO 1/8 GP 4wd

$366.00 Original price was: $366.00.$99.99Current price is: $99.99.

- Safeguard Your Shopping Experience

- Experience Quality, Shop with Us

- No Compromise on Quality

- Shop the Best Quality Online

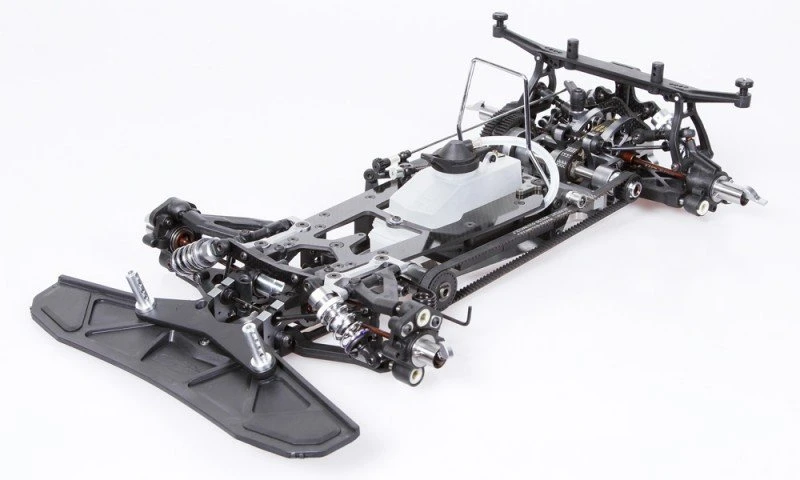

The Serpent Viper-EVO is the next step in the continiuous development of this

very demanding 1/8 scale racing class, the pinnacle of rc car racing. The Viper

977-EVO is all about refinement, to make a superb car even better. A fully adjustable

race chassis to the latest spec and technology. Lighter, stronger, new geometry,

more tuning features.

Specifications:

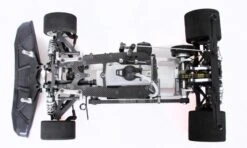

- Class: 1/8th scale gas on-road, IFMAR rules

- Purpose: High-end competition

- Weight: 2.420kg (depending on radio gear)

- Track-width rear: 260mm – 266mm

- Track-width front: 250mm – 260mm

- Wheel base: Adjustable 296 – 300mm +/-1.7mm

- Not included: Engine, pipe, body, radio equipment, wheels, tires, battery

pack - Chassis: 5mm 7075 aerospace quality aluminium

- Radio plate: 2.5mm carbon fibre,

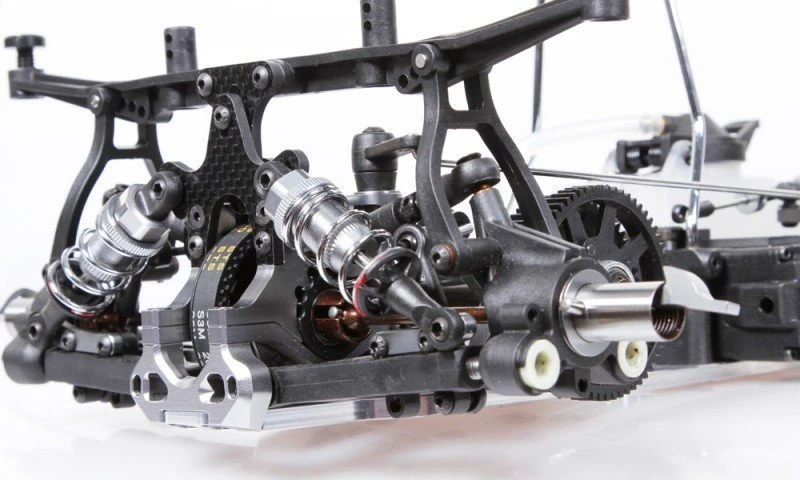

- Suspension: Independent double wishbone suspension

- Shock absorbers: RCM shock absorbers

- Fuel tank: 125cc design

- Rear axle: Solid rear axle

- Front axle: Aluminium front axle with one-way bearings

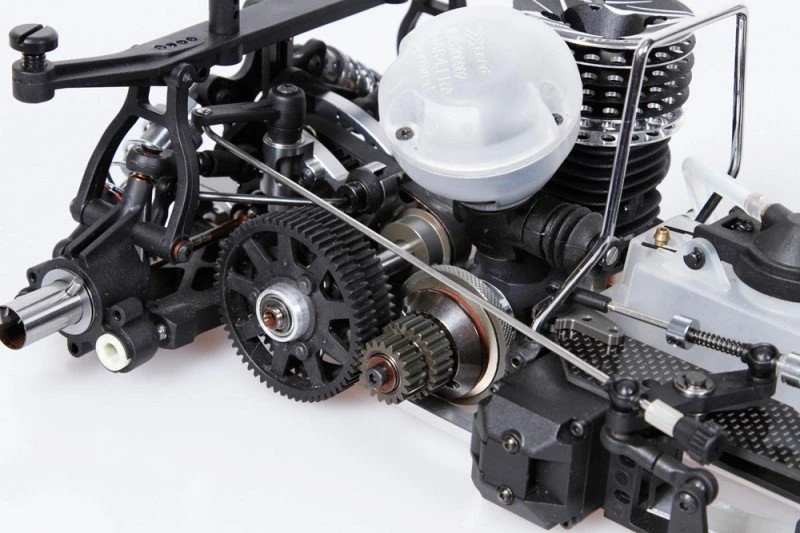

- Gearbox: Lightweight 2-speed XLi8

- Clutch system: Centax true Motion clutch system

- Instructions: Full colour Instruction manual online / PDF

- Adjustability: Camber, Caster, Down-stops, Up-stops, Toe-in, Track width,

Wheel base, Front & rear roll centre

Features:

- 2-speed gearbox SL8 XLi with superlow inertia

- Composite 2-speed gears with 0.8 pitch

- Centax hardcoated alu clutch gears with 0.8 pitch

- Aluminium chassisplate in 7075 T6 with optimised flex and weights slide

- carbon fibre 2.5mm radioplate with aluminium mid-flex system

- aluminium central flex system with bearings

- front bumper with inserts

- new geometry with narrower front end

- improved rear bodymount

> Viper 977 EVO 1/8 GP 4wd (#903015)

> Description · News (7) · Specifications · Images (41) · Downloads (6) ·

Spares (178) · Optionals (86) · Setups (24)

Brand: Serpent

Product Type: Gas Cars > 1/8

Viper 977 EVO 1/8 GP 4wd 2013-2014 IFMAR TQ and World Champion, Japan Tadahiko

Sahashi with Viper 977 Gaspowered toplevel racecar with 4wd, belt-drive, Centax

true motion clutch, XLi8 gearbox, flex-system front and rear, brake on rear

axle, front one-ways, rear solid axle, ballraced anti-rollbars. A fully adjustable

race chassis to the latest spec and technology. Lighter, stronger, new geometry,

more tuning features. Design by Michael Salven

Related products

– Serpent S120 LTR 1/12 pancar EP (#410006)

– Serpent F110 Formula 1/10 EP SF2 (#410061)

– Cobra GT 1/8 onroad (#600040)

– Natrix 748 TQ 1/10 200mm gp car (#804008)

– Viper 977-e 1/8 scale 4wd EP (#904002)

> Description

Serpent Viper 977-EVO

1/8 scale gas onroad car

Serpent has been developing 1/8 scale onroad rc cars since 1977, officially

as company since roughly 1980. That is over 35 years of of race and development

experience combined !

The Serpent Viper-EVO is the next step in the continiuous development of this

very demanding 1/8 scale racing class, the pinnacle of rc car racing. The Viper

977-EVO is all about refinement, to make a superb car even better. Ready to

defend the 2013-2014 World Championship TQ and title by Tadahiko Sahashi from

Japan.

Bodymount rear

Rear floating bodymount

Extra ribs and more material is added to increase the stiffness of the rear

bodymount and a 4th hole is added both sides for more tuning options

Bumper

Front bumper with inserts

The newly developed front aero type bumper is a very durable unit, which as

extra feature offers removable inserts. Its very easy and quick to test with

or without inserts in a matter of seconds.

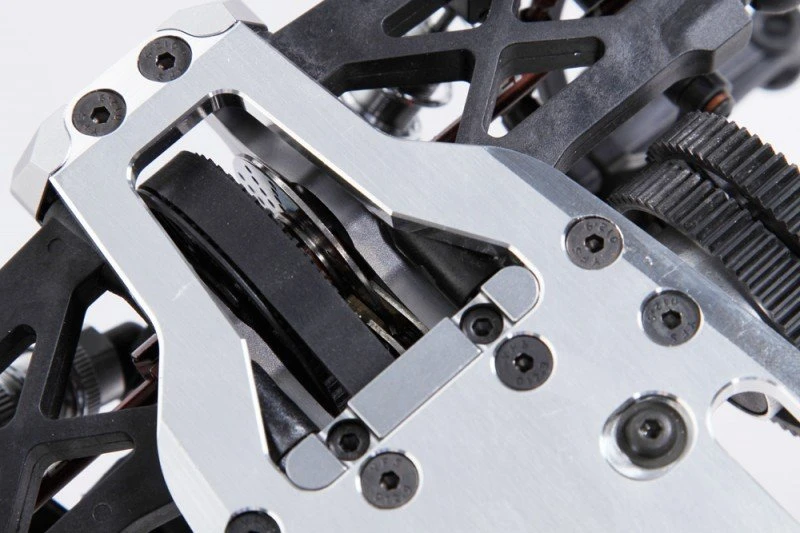

Central flex

Aluminium central flex system with bearings

The system consist of a lower and upper anodised aluminium section, connected

with screws for zero flex, or with bearings inside for some controlled flex.

It needs removal of only 2 screws to go from fixed to controlled flex.

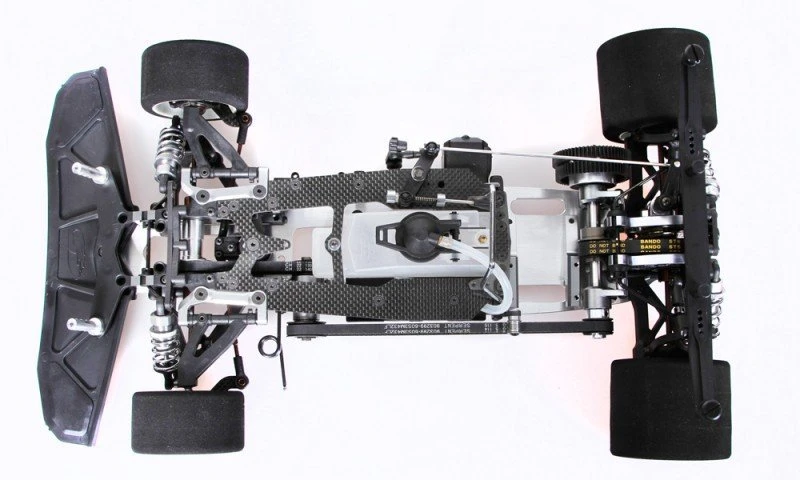

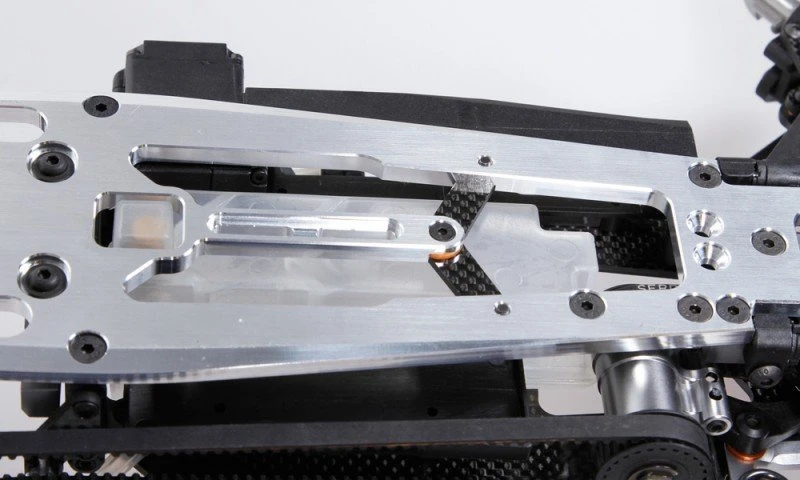

Radioplate

Carbon fibre 2.5mm radioplate with aluminium mid-flex system

The stiff carbon fibre radioplate is one piece again with the flex system moving

to the center of the car, just behind the tank.

Chassis

Aluminium chassisplate in 7075 T6 with optimised flex and weights slide

The chassisplate is a very important part as central unit in the car. The flex-characteristic

is a major point, as well as weight balance with the sliders we apply and the

dissipation of heat from the engine. The chassis is narrower in the front to

allow a slightly different geometry. 2 sets of front lower pivotpins holders

are included to change the geometry, run it narrow or wide. Machining of the

chassis allows flex in a different area as before, and can be influenced by

using the carbon brace.

New geometry with narrower front end

The narrower chassis in front allows to run a slighly different geometry in

the front.

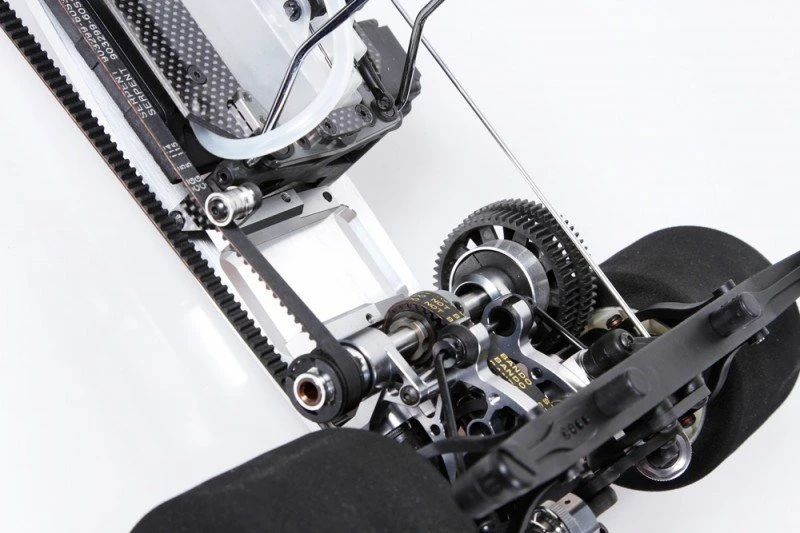

Centax

Centax hardcoated alu clutch gears with 0.8 pitch

To go with the 0.8 pitch gears, the Centax gearpinions also needed to go to

the 0.8 pitch. The precision machined and hardcoated gears are durable and smooth.

The Centax clutch is a Serpent innovation from the early nineties, and is in

use by almost all brands now.

Key new features

- 2-speed gearbox SL8 XLi with superlow inertia

- Composite 2-speed gears with 0.8 pitch

- Centax hardcoated alu clutch gears with 0.8 pitch

- Aluminium chassisplate in 7075 T6 with optimised flex and weights slide

- carbon fibre 2.5mm radioplate with aluminium mid-flex system

- aluminium central flex system with bearings

- front bumper with inserts

- new geometry with narrower front end

- improved rear bodymount

- Independent suspension with hydraulic shocks

- Front shaft with oneways and rear solid axle

- Aluminium bearingblocks front and rear

- Central rear axle brake

- Front cvd , rear dogbone drive, both with quick change wheel system/axles

- Ball raced front and rear anti-roll bars

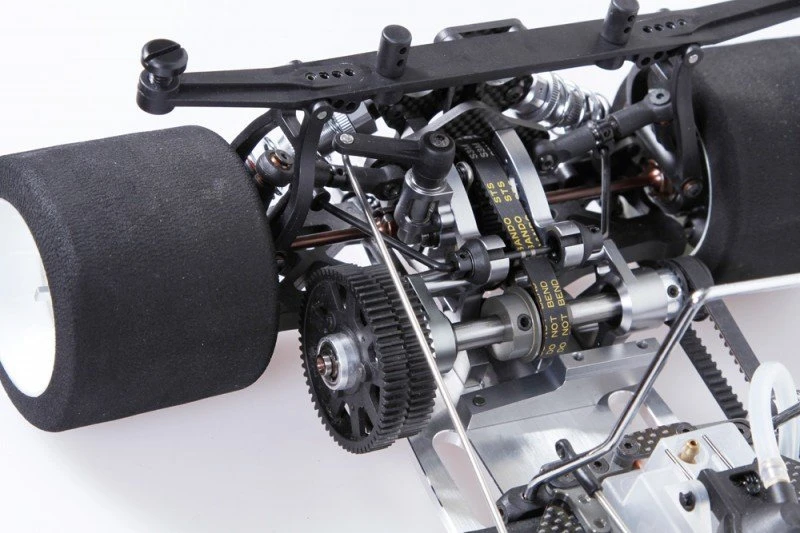

2-speed gearbox SL8 XLi with superlow inertia

All the parts of the gearbox have been made smaller and as light as possible,

to lower inertia even further, still keeping durability on top of the list.

The gears changed to a 0.8 pitch which is smoother than the original one. The

Serpent gearbox system was our innovation in the late 80-ties and the system

hardly changed, only optimised, and now as system in use with all other brands

.

Bodymount rear

Rear floating bodymount

Extra ribs and more material is added to increase the stiffness of the rear

bodymount and a 4th hole is added both sides for more tuning options

Bumper

Front bumper with inserts

The newly developed front aero type bumper is a very durable unit, which as

extra feature offers removable inserts. Its very easy and quick to test with

or without inserts in a matter of seconds.

Central flex

Aluminium central flex system with bearings

The system consist of a lower and upper anodised aluminium section, connected

with screws for zero flex, or with bearings inside for some controlled flex.

It needs removal of only 2 screws to go from fixed to controlled flex.

Radioplate

Carbon fibre 2.5mm radioplate with aluminium mid-flex system

The stiff carbon fibre radioplate is one piece again with the flex system moving

to the center of the car, just behind the tank.

Chassis

Aluminium chassisplate in 7075 T6 with optimised flex and weights slide

The chassisplate is a very important part as central unit in the car. The flex-characteristic

is a major point, as well as weight balance with the sliders we apply and the

dissipation of heat from the engine. The chassis is narrower in the front to

allow a slightly different geometry. 2 sets of front lower pivotpins holders

are included to change the geometry, run it narrow or wide. Machining of the

chassis allows flex in a different area as before, and can be influenced by

using the carbon brace.

New geometry with narrower front end

The narrower chassis in front allows to run a slighly different geometry in

the front.

Centax

Centax hardcoated alu clutch gears with 0.8 pitch

To go with the 0.8 pitch gears, the Centax gearpinions also needed to go to

the 0.8 pitch. The precision machined and hardcoated gears are durable and smooth.

The Centax clutch is a Serpent innovation from the early nineties, and is in

use by almost all brands now.

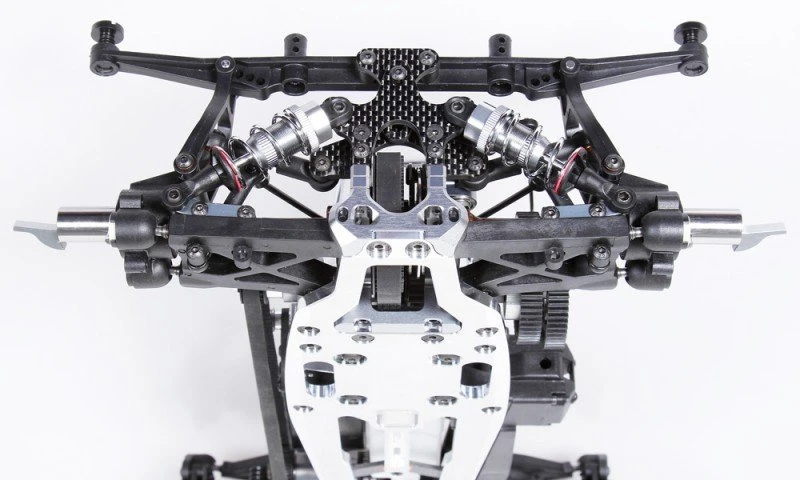

The durable composite front bodyposts are excentric , to allow moving the body

to front or back a few mm to optimize steering / downforce.

The steeringblock , which can be mounted left or right, offers a system to

change the axle position more to front or back giving a trailing or leading

steering, and the ability to change the kingpin-inclination and offset. The

steeringblock features an aluminum plate to connect the steering-rods, 2 options

for Ackermann.

The spring-steel steering-rods are fastened to the alu steeringplates, which

mount to the new steeringblocks. Optional carbon fibre disks can be mounted

on the side of the uprights to stiffen the assembly and for aerodynamic reasons.

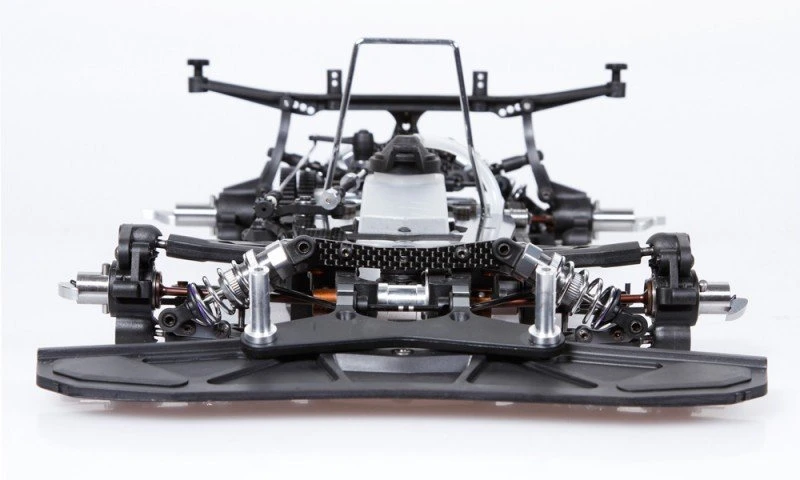

The long durable front lower wishbones, are mounted superlow in the car, and

feature a semi covered leg for the inner suspension pin and the pivot link for

the front anti-roll bar system, its also has an extension for the down-stop

screw . The lower arms hold the lower alu shockmount plate, which allows a further

out and higher mounting point for the front shocks. The strong upper arms in

can be used left and right. The front lower arms connect to the alu front bracket

on very low nylon holders. The kit includes 2 versions, wide and narrow . This

whole system also enables you to replace a front driveshafts very quick and

easy.

The longer upper arms are mounted between the anodized aluminum top brackets,

which also hold the suspensionpin inserts to allow camber-change adjustments

with 3 possible inserts . Below the alu top-brackets spacers can be used to

change angle or height. Caster spacers are used as simple clips on the upper

pivot pins. Same clips are also used on the lower pins to change wheelbase.

The topmounted composite bracket gives extra stiffnes to the front section,

it holds the 3mm thick carbon fibre front shocktower and allow for the down-stop

screws.

The ballraced front anti-roll bar is a wire type, with very easy and fast open

access on the front, captured in the alu front braces. The standard wire is

2.5mm and 2 other as options. The pivotballs link system directs the power to

the bar in a smooth way and easy to adjust the tweak with the captured pivotball.

In the front the alu front axle with Japan-made one-way bearings features now

an improved pully assembly, free of play and super-true. Springsteel drivecups,

strong, long and thin spring-steel driveshafts with CVD system, and ballraced

springsteel wheelaxles with alu quick-change levers. The open front end design

allows for very fast and easy removal of the front axle or parts.

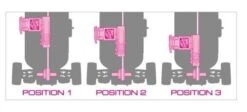

The springloaded servo-saver allows easy and fast Ackermann settings. The servo-saver

features a top mounted insert which can be used in 3 positions. Another 2 Ackermann

positions on the steeringblocks.

The steeringblocks and rear uprights connect to the arms with springsteel 8.5mm

pivotballs , which run very smooth and well protected in nylon cups, and are

easy to adjust with an allen tool.

2.5mm carbon fibre radioplate with the the center flex-control system. The

radioplate holds the fueltank, the receiver battery and the integrated electronics

bracket/box, as well as the center flex system

The new center flex system consist of a lower and upper CNC machined aluminium

bracket and a smal carbon brace. The upper one is fixed to the radioplate and

the lower one to the center radioplate mount.

In rigid standard positon the upper and lower brackets are mounted fixed with

2 screws.

In the flex position the 2 bearings are in place and with the 2 screws dis-assembled,

offer the central chassis flex.

Compact composite brace and box in one, which holds and protects the receiver

and mounts both servo?s, which both lay on their sides, as low as possible,

just a small clearance to allow for chassis flex. The cap of the receiverbox

offers a unique yet simple and safe holder for the cable connectors of the receiver,

which works as a simple switch and is very accessible.

The optional carbon transponder brace mounts to the integrated electronics brace.

When using a small receiver, the box has space to hold the transponder too,

but must be tested for function before the race. In our test it worked.

Low 125ccm fueltank in a long and narrow design, with a premounted bronze filter.

The narrow tank will ensure a better fuel-supply to the engine, as the fuel

can move less from side to side. The labyrinth inside the fueltank will also

keep the fuel more stabile and avoids foaming. The tank also has elevated sections

in the front, which make sure the fuel stays close to the filter when the tank

is amlost empty. This creates like a warning signal a few seconds before the

tank goes fully empty, so you can try to find a safer place to park. The fueltank

has a strong springloaded cap and silicone rubber shaped seal, and has a connection

for the pressure line. The inner bottom of the tank allows for mounting inserts

to reduce volume if needed.

The composite nylon radioplate bracket, holds the rear part of the radioplate

and the strong chromed angled roll-bar, and also mounts the adjustable ballraced

belt-tensioner. An aluminum one is optional.

The majority of the topmounted screws are in allen 2.0mm size, except for the

upper suspension brackets in 2.5mm.

The batteryholder between the tank and side belt , is made to fit the more

common Lipo packs. There is also enough space to fit a regular batterypack.

The holder incorporates an easy spacing system to allow this.

The light, hollow 8mm hardcoated aluminium middle shaft is kept rigidly in

place a small, low placed and light alu holder, which also holds the spring-type

exhaust-wire.

The final drive ratio of the car is 2.286

28T front pulley

18T mid-inner pulley

25T mid-outer pulley

19T outer lay-shaft pulley

21T inner layshaft pulley

48T rear axle pulley.

All the superround and true pullies have holes in the side flanges to allow

dirt and dust to move out easier. The 977 has the latest pullies, with more

teeth, so larger diameter which makes the belts run smoother, with less friction.

The belts are low friction type as standard, rear one as 8mm, side in 6mm and

front 6mm too. The adjustable ballraced belt-tensioner ( carbon, alu) keeps

the sidebelt running smooth.

The low seated anodized aluminum engine mounts keep the engine well positioned

and aligned and transfer heat to the chassis in the best way.

The rear end construction with the alu brackets holds the brake and rear axle.

Its open design allows for eas of maintenance and cleaning, and needs very few

screws to dis-assemble. Replacing a belt in case needed, is simple and very

fast too. The excenter on the rear shaft allows for belt tensioning. The whole

rear end can be removed as one unit from the chassis, with very few screws.

The rear axle sits very low in the car, to achieve more mechanical grip.

The brake is on the rear axle, next to the solid axle pully. This reduces the

inertia effect of the brakedisc a lot because the rear axle spins much slower

than the twospeed shaft. Also the brake-stress on the rear belt is almost gone.

Its a very compact system and well protected against dirt, but still open enough

to allow for sufficient coolng. The swimming ventilated brake-disk rotates on

the rear axle and the springloaded cam-operated brake pads will provide all

the stopping power you may need. The race brake pad material is baked on strong

steel plates and allows very precise braking with lots of brake-feel / feedback.

Instead of a cable we opted for the well-proven wire-linkage of all Serpent

cars.

The ballraced brake activator is bolted in a light alu holder to the right rear

bracket.

The ballraced rear anti-roll bar mount in steel adaptors, which run in nylon

spacers in the alu holders as integral part of the rear brackets, with 2.5mm

as standard wire and 2 other as options. The anti-roll bar links to the rear

lower arms with adjustable trackrod guidance.

The solid rear axle with lightweight 48T pulley in Serpent springsteel, 9mm

wide with 4 slots for the pin.

The aluminium rear brackets and the 2-speed layshaft holders have small ears

which allow for mounting of the optional alu or rubber spacer, to control flex.

Either full flex, no spacer, or some flex with rubber spacer, or zero flex with

the aluminium spacer.

The suspension bracket and rear plate hold the pins firmly and have composite

roll-center inserts to allow for fast and precise changes.

In the rear strong springsteel driveshafts , springsteel wheel-axles with alu

quick-change levers and a springsteel rear axle. Very durable and lasting drivetrain

The long durable rear lower wishbones can be used left and right. The lower

rear arm holds the low mounted link for the rear anti-roll bar and holds the

alu mounting plate of the rear shocks, which allows a position which is very

far to the rear and to the outside for best performance/ geometry. The lower

arms also hold the easily accessible down-stop screws. Nylon clips are used

on the lower rear pins to change wheelbase.

The durable composite uprights hold the ballraced spring steel wheelaxles,

with aluminium quick-change levers. The 8.5mm piotballs are used to adjust camber

fast and easy with the smooth hex-shaped plugs . The arms of the floating bodymount

mount to the top of the uprights. On top of the up-right spacers can be added

under the pivotball to change rollcenter and camberchange.

Optional carbon fibre disks can be mounted on the side of the uprights to stiffen

the assembly and for aerodynamic reasons.

The adjustable rear upper camber links mount to the rear carbon camberplate

with 2 positions .

The rear floating bodymount is mounted on the up-rights with 2 arms and held

in place by a carbon-fibre-steel guider. The mount has 4 positions each side

to choose from, depending on body In use. The end of the mount allow for mounting

body-supports , with full threading to allow exact positioning. The system leads

the available downforce direct onto to the uprights to the tyres.

Composite 2-speed gears with 0.8 pitch

Smaller lighter gears and with 0.8 pitch for smoothness and performance. The

precision machined and hardcoated gears are durable and smooth.

The innovative Serpent True Motion Centax clutch is fitted. Serpent as inventor

of the original centax clutch, has developed the clutch over the years and the

current version excels in power throughput , reliability and eas of setting.

The standard version comes with a steel clutch bell, red centax show and hard

anodized clutch-gears.

The kit features high speed ballbearings, mostly sealed ones with aeroshell

lubrication or grease. All bearings in the car ( except for the servosaver and

brakecam) are seated in nylon bushings to reduce vibrations and play.

The shockabsorbers are the latest Serpent RCM units with membrames. The threaded

houses with setting-nuts ( o-ring inside) makes ride height changes easy and

precise. The RCM shocks are very smooth, and easy to assemble and fill. The

shocksprings are selected, matched, flatgrinded, colorcoded units, equal length

front and rear.

Be the first to review “SER903015 Serpent Viper 977 EVO 1/8 GP 4wd” Cancel reply

Related products

R/C On-Road Car

R/C On-Road Car

R/C On-Road Car

R/C On-Road Car

32798 Kyosho – MINI-Z Racer MR-03EVO Chassis Set (N-MM2/4100KV)

R/C On-Road Car

R/C On-Road Car

R/C On-Road Car

Reviews

There are no reviews yet.